Design and Construction of TDAE

Treated Distillate Aromatic Extraction (TDAE) is a widely used process for producing high-quality Process Oil, which contains a minimal amount of aromatics that can be carcinogenic. During the production of base oil through vacuum distillation and de-asphalting processes, aromatics are produced as a byproduct. As a result, the outlet production contains a considerable amount of aromatics, along with valuable oils used in rubber manufacturing. However, it is essential to remove cyclic aromatics from the final product to ensure it meets the necessary safety regulations.

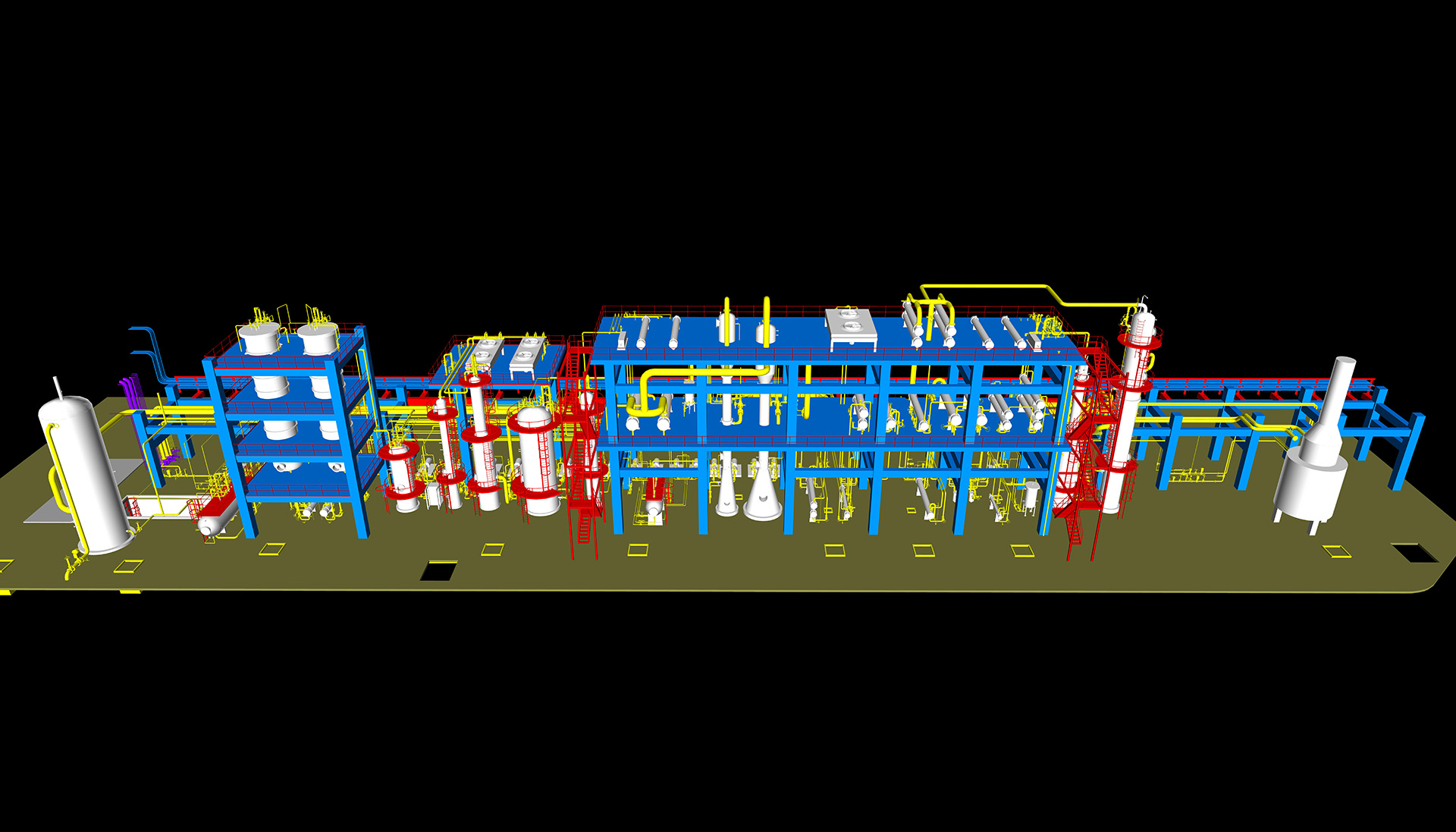

To produce high-quality process oils that comply with European Union regulations, Sepahan Oil Industry has initiated the TDAE plant construction project. The basic engineering design was conducted by EDL, a company based in Germany, while the technical engineering group at Phoenix Oil and Gas Company is responsible for implementing the detailed design.

The TDAE plant will enable the production of process oils of exceptional quality, free from carcinogenic aromatics, making it a safer and more reliable option for use in rubber manufacturing. With our commitment to adhering to safety and environmental regulations, the TDAE plant will enable us to deliver superior products that meet international standards.

Service:

Detailed Engineering Services

Project Duration:

8 months

Client:

Sepahan Oil Co.

Owner:

Naam Avaran Delvar Co.

Licensor:

EDL Co.

Person Hour:

32000 hours