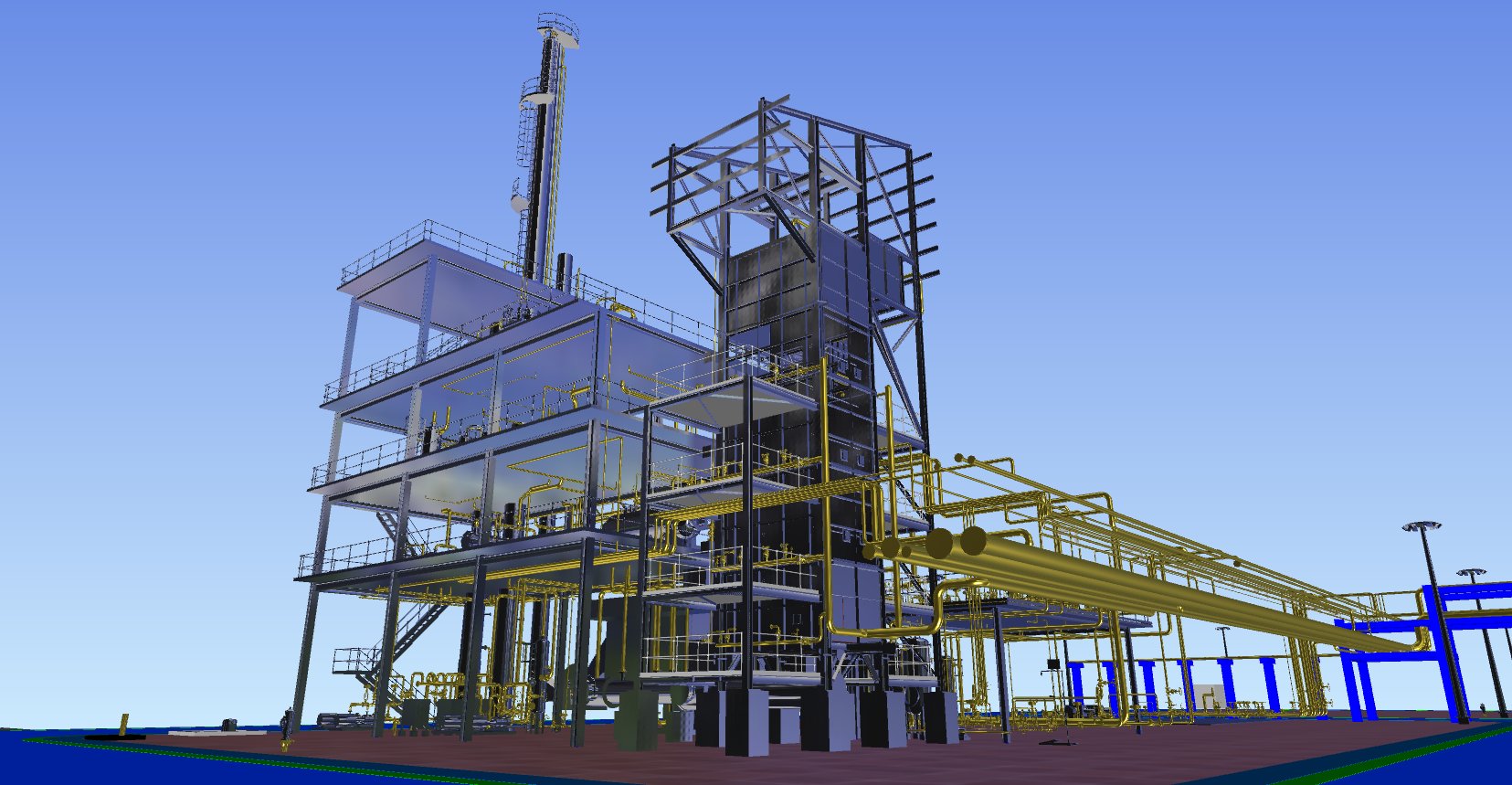

Construction of Hydrogen Plant

The hydrogen plant is a vital component of the hydrogen peroxide production plant. It involves the conversion of natural gas into syngas using the steam reforming method (SMR), followed by purification through an Amin absorber column to remove carbon dioxide. The CO2-less gas is then directed to the Pressure Swing Adsorption (PSA) system, which separates hydrogen from carbon monoxide. The resulting CO and H2 streams are subsequently used in the production of Formic Acid and Hydrogen Peroxide, respectively.

The design and construction of the hydrogen plant presented significant technical challenges that had previously been addressed only by advanced established firms. However, the design team at our knowledge-based enterprise was able to successfully design the hydrogen plant, marking the first time such a feat had been accomplished by a domestic firm.

In addition to the hydrogen unit, our engineers also designed all the necessary utilities, including water treatment, steam generation, a cooling water system, and all the required buildings. The detailed design of these utilities was done with precision and care, ensuring optimal efficiency and functionality.

Overall, our company's successful completion of this plant project demonstrates our expertise in advanced industrial processes and our commitment to excellence. Through the use of cutting-edge technology and the ingenuity of our talented team, we have established ourselves as a leading player in the field of Hydrogen Peroxide production.

Service:

Detailed Engineering Services and Equipment Purchase

Project Duration:

20 months

Client:

Kimia Hydrogen Peroxide Co.

Licensor:

Petro Process Phidar Engineering Co.

Person Hour:

58000 hours